Manufacturer of cosmetic amenities

Amenities

Valquer Laboratorios joins forces with Jypesa Hospitality to form a new company called Jypesa Europa, aimed at developing and offering amenities, dispensers and complimentary products of the highest quality to the Hospitality channel (Hotels, Hospitals, Residences, Gyms, etc.).

The innovative power of Valquer Laboratorios, with its sustainable positioning (plastic-free and “waterless” (without water)), combined with Jypesa’s industry experience, makes the new proposal for Europe highly attractive to customers.

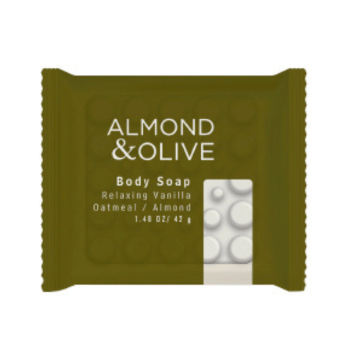

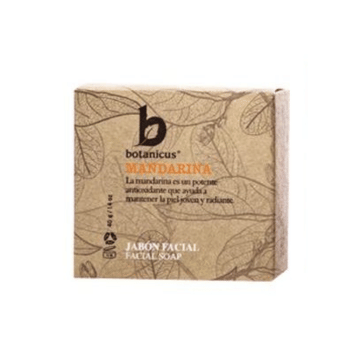

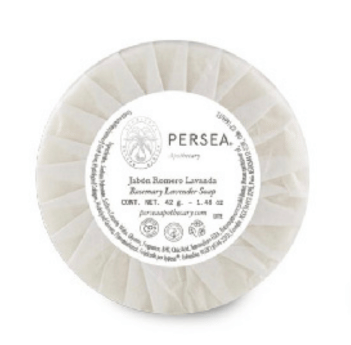

Examples of Amenities

A partner for your own

brand of amenities

Recommendations from our CEO:

- Find a team of people with whom you feel affinity and trust to develop your amenities project.

- Select a laboratory and factory that already market their own products (shampoos, gels, lotions, perfumes, sunscreens…), which will provide you with greater security.

- Choose a laboratory with a clear focus on R&D+i, offering premium formulas and aligned with current trends: natural, biotechnological, effective, vegan, and sustainable cosmetics.

- Check the quality certifications, at a minimum: ISO 9001, ISO 14001 (Environment), ISO 22716 (GMP) or IFS.

- Visit the laboratory and factory facilities of your future partner.

Packaging for amenities

What do we offer?

10 steps for your own brand of amenities

01

Contact:

We receive your request through our contact form.

02

Technical-Commercial Meeting:

Our advisors will communicate with you, gathering detailed information about the amenities project and will assess its feasibility.

03

Feasibility and Offer I:

If the project is feasible, a budget for the formula development is provided. If an already available or “ready to go” formula is chosen, we would proceed to point number 5.

04

Specific R&D+i:

Our lab qualitatively develops the required formula, sending samples for approval. Once the formula is validated, we will work on packaging options and the various compatibility/stability tests.

05

Offer Validation II:

Offer II for the production of the final amenities (formula + packaging) is sent. Once validated, internal codes are created, and the creative process (design and texts) begins.

06

Creativity Validation:

The client designs and confirms that the creativity and texts are correct, allowing the procurement of materials to proceed.

07

Materials Reception:

All materials are received at our facilities and are inspected and approved by our Quality team before proceeding to production.

08

Production:

The manufacturing and packaging of the amenities are carried out in automated and authorized facilities.

09

Quality Control:

Extensive quality controls (physical and microbiological) are conducted before the batch is released.

10

CPNP Registration and Commercialization:

The amenity is registered on the European portal and is ready for commercialization.