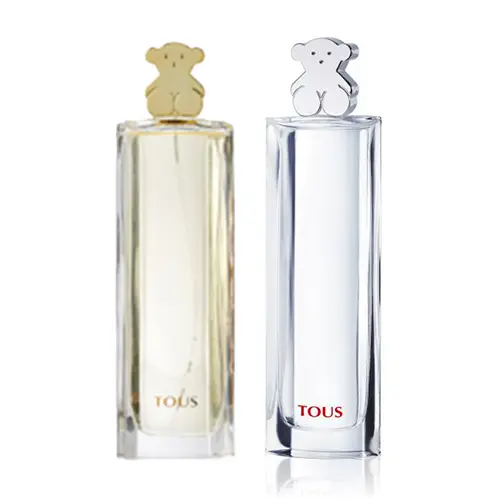

Perfume manufacturer and packager

Third-party perfume manufacturer and packager

Our laboratory and factory provide a development, manufacturing, and packaging service, either as “full service” or “turnkey”, for high-end perfumery projects of various sizes and quantities: small (1,000 units), medium and large productions.

We collaborate with internationally renowned perfumers and have a specific team dedicated to handling these highly personalized projects.

We specialize in high-end perfumery, niche perfumery and artisanal perfumes.

Perfumes created

We accompany your perfume to success!

Experts in fragrances, aromas, essence suppliers,

and many packaging options: bottles, cases, finishes, etc.

Our machinery allows us to adapt to

small (1,000 units), medium and large productions.

Recommendations from our CEO:

- Find a team of perfume experts you can connect with and feel comfortable developing your fragrance project.

- Look for a laboratory and factory with experience in manufacturing perfumes for various prestigious brands. This will provide you with greater security and confidence.

- Consider the possibility of expanding your perfume line, thinking beyond the initial production.

- Verify quality certifications, at a minimum: ISO 9001, ISO 14001 (Environment), ISO 22716 (GMP), or IFS.

- Visit the facilities of the laboratory and factory of your potential partner to get a close look at their production process.

- It is highly recommended that the laboratory has its own regulatory department to ensure the correct registration and internationalization of perfume products.

Perfume packaging

What we offer?

10 Steps for Your Own Perfume

01

Contact

We have received your request through our contact form.

02

Technical-Commercial Meeting:

Our specialized team will communicate and gather detailed information about the perfumery project. The feasibility of the project will be studied.

03

Feasibility

and Offer I:

If the project is viable, the budget for the development of the perfume is shared, based on the initial requirements.

04

Specific R&D&I:

Our team will develop various perfumes olfactively, supported by the best international perfumers. Samples are sent for approval. Once the fragrances are validated, we work on packaging options and conduct compatibility and stability tests.

05

Validation of Offer II:

Offer II for the production of the final perfume (essence + packaging) is sent. Once validated, internal codes are opened, and the creative process (design and texts) begins.

06

Creativity Validation:

The client confirms that the designs and texts are correct, so the materials are procured.

07

Materials Reception:

All materials are received at our facilities and are reviewed and approved by Quality before proceeding to production.

08

Production:

The essence maceration and perfume packaging are carried out in authorized facilities.

09

Quality Control:

Exhaustive quality controls (tightness, physical, leakage, etc.) are performed before the batch is released.

10

CPNP registration and commercialization:

We perform product tests on both the formulation and packaging to ensure compliance and readiness for market launch